Core Material Parameters & Performance Advantages

Material Characteristics

It adopts 6061-T6 aluminum alloy material, where "6061" is the aluminum alloy grade (containing alloying elements such as magnesium and silicon) with good machinability and weldability; "T6" represents the heat treatment state (solution heat treatment followed by artificial aging). After this process, the mechanical properties of the profiles are significantly improved.

Light Weight: Density as low as 2.7g/cm³, approximately 1/3 that of steel, which can significantly reduce the overall weight of mechanical equipment and door & window products, lowering installation and transportation costs.

High Strength: Tensile strength ≥310MPa and yield strength ≥276MPa, far exceeding ordinary aluminum alloy profiles. It can withstand large loads and impacts, performing excellently in scenarios such as mechanical frame load-bearing and door & window wind pressure resistance.

Corrosion Resistance: Possesses good corrosion resistance, not easy to rust during long-term use, reducing maintenance costs. These performance indicators meet the requirements of ISO 2108:2018 (Aluminium and aluminium alloys - Temper designations) for T6 heat treatment state.

Compliance Guarantee

The products are strictly produced in accordance with GB/T 6892-2021, with indicators such as dimensional deviation, surface quality, and mechanical properties complying with specifications. Each batch of products is accompanied by a material inspection report, clearly marking chemical composition (e.g., magnesium content 0.8%-1.2%, silicon content 0.4%-0.8%) and mechanical property test data to ensure material compliance. Re-inspection by third-party testing institutions is supported, providing customers with peace of mind during use—consistent with the testing standards of ASTM E1251/E1251M-18 (Standard Practice for Registration of Aluminum and Aluminum Alloy Products).

Regular Specifications & Customization Services

Regular Specifications

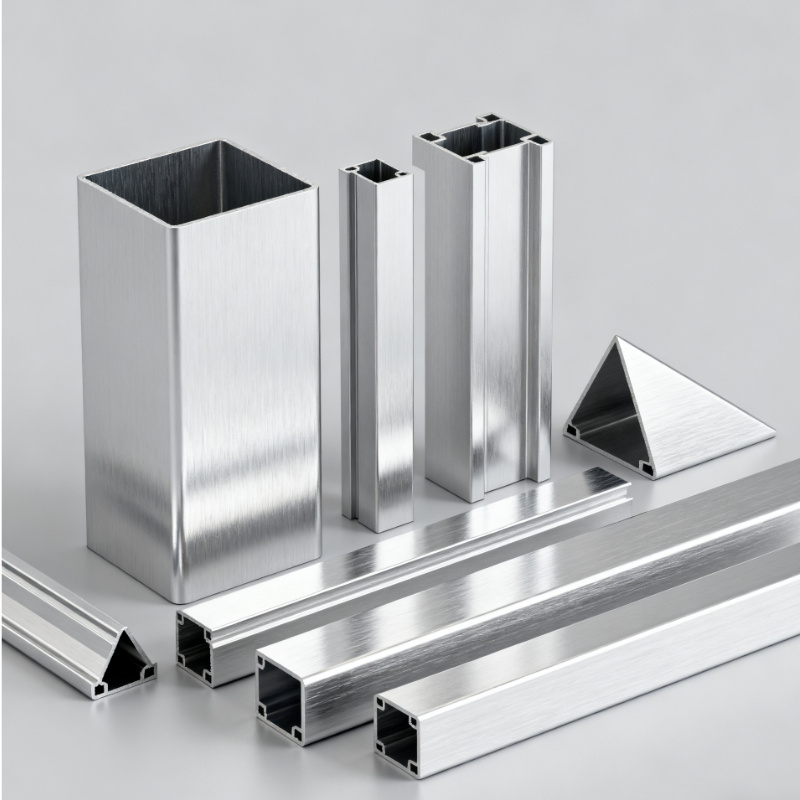

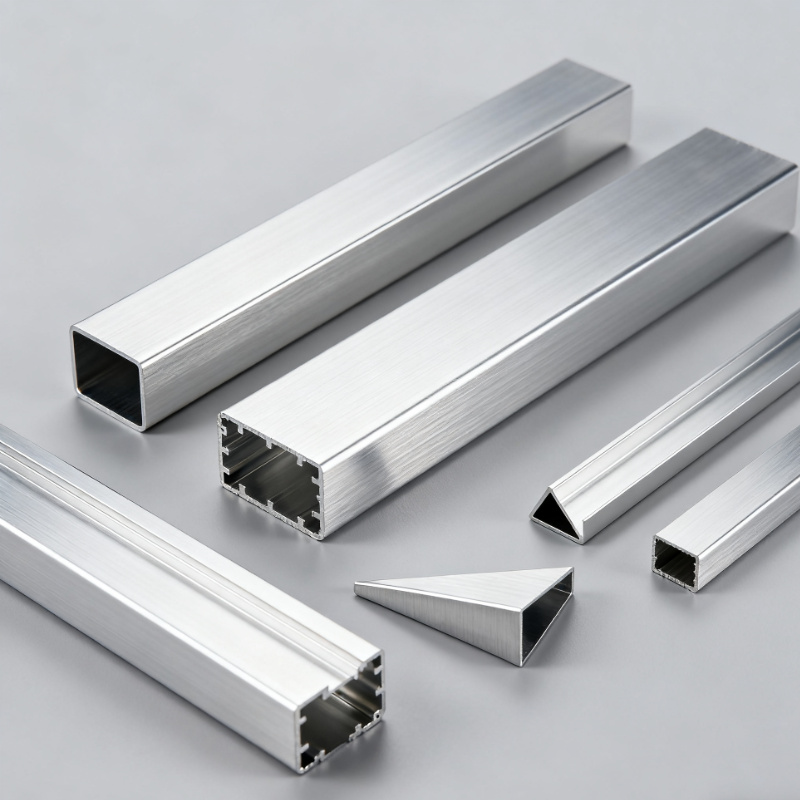

It covers a variety of commonly used profile types:

Rectangular Tubes (20×40mm): Suitable for lightweight frames of mechanical equipment and horizontal supports of doors & windows.

Square Tubes (30×30mm): Combining aesthetics and load-bearing capacity, applicable to equipment guardrails and door & window frames.

Angle Aluminum (30×30×3mm): Convenient for right-angle connection and structural reinforcement, often used in mechanical casings and door & window corners.

All regular-specification profiles are formed by precision extrusion technology, with flat and smooth surfaces and high dimensional accuracy (length deviation ≤±2mm/m), which can be directly used without secondary processing—meeting the dimensional tolerance requirements of ISO 6362-1:2018.

Customized Forming

Customization of profiles with special sizes and shapes is supported according to customer needs: the minimum wall thickness can be 0.8mm (subject to structural strength requirements), and customized special-shaped cross-sections (e.g., groove-shaped, I-shaped) and specific lengths (up to 6 meters) are available. During the customization process, a professional technical team provides structural optimization suggestions based on the customer's application scenarios (e.g., mechanical stress requirements, door & window installation space), ensuring the customized profiles not only meet size requirements but also have sufficient mechanical properties. Meanwhile, the customization cycle is shortened, with regular customized orders deliverable within 7-15 days.

Industry-Specific Services & Process Support

Exclusive Services for Machinery Enterprises

To meet the needs of mechanical manufacturing customers, surface treatment processes such as anodizing and spraying are provided:

Anodizing: Forms a uniform oxide film (thickness ≥10μm) on the profile surface, improving corrosion resistance and wear resistance, suitable for equipment parts used outdoors or in humid environments.

Spraying (e.g., powder coating, fluorocarbon coating): Offers multiple color options, combining decoration and protection to meet equipment appearance design needs. The coating has strong adhesion (cross-cut test ≥Grade 1) and is not easy to fall off, complying with ASTM D3359-17 (Standard Test Methods for Measuring Adhesion by Tape Test).

Exclusive Services for Door & Window Enterprises

Deep processing services are provided for door & window processing customers, including precision cutting (cutting error ≤0.5mm), drilling (hole diameter deviation ≤±0.1mm), and milling grooves. Semi-finished profiles ready for assembly are directly delivered, reducing on-site processing procedures for customers and improving door & window assembly efficiency. Meanwhile, customized protective packaging (e.g., pearl cotton wrapping, cardboard box separation) is provided according to the transportation and storage needs of doors & windows, avoiding surface scratches or deformation of profiles due to collision and friction during transportation, and ensuring product delivery quality.

Supply & After-Sales Guarantee

Stable Supply

We cooperate with large domestic aluminum alloy profile production bases, with multiple extrusion production lines. Regular-specification profiles have sufficient inventory, enabling same-day ordering and next-day delivery; customized profile production capacity is stable, with a monthly capacity of over 500 tons, which can meet the bulk procurement needs of machinery and door & window enterprises. Long-term contract supply is supported, with batch delivery according to the customer's production plan to avoid inventory backlogs.

After-Sales Support

A complete after-sales response mechanism is established. During product use (e.g., installation adaptation, performance questions), customers can contact the technical team at any time for guidance; if there are product quality problems (e.g., excessive dimensional deviation, surface defects), unconditional return and exchange are available after verification, with related freight borne by us. Meanwhile, we assist customers in analyzing the causes of problems to avoid similar issues in the future, fully protecting customer rights and interests—aligning with the after-sales service standards of ISO 10002:2018 (Quality Management - Customer Satisfaction - Guidelines for Complaints Handling in Organizations).

Address:Room 1318, Unit A, Building 17, Headquarters Economic Park, No. 88 Gaohua Central Road, Tangquan Sub-district, Pukou District, Nanjing, Jiangsu, China

Address:Room 1318, Unit A, Building 17, Headquarters Economic Park, No. 88 Gaohua Central Road, Tangquan Sub-district, Pukou District, Nanjing, Jiangsu, China Tel:+86 18551848444 (Mr. Wang)

Tel:+86 18551848444 (Mr. Wang) E-mail:info@xyytrade.cn

E-mail:info@xyytrade.cn